Business Type:Manufacturer

Country/Region:India

Ddu Verified

HOT Rank

MAHAVIR SURGICAL ENTERPRISES

We are professional supplier of lumbo sacral belt,knee braces,cervical collar,wheelchairs,walking sticks,walkers,arm sling,diapers,maternity pads,elbow support.

Business Type:Manufacturer

Country/Region:India

Ddu Verified

HOT Rank

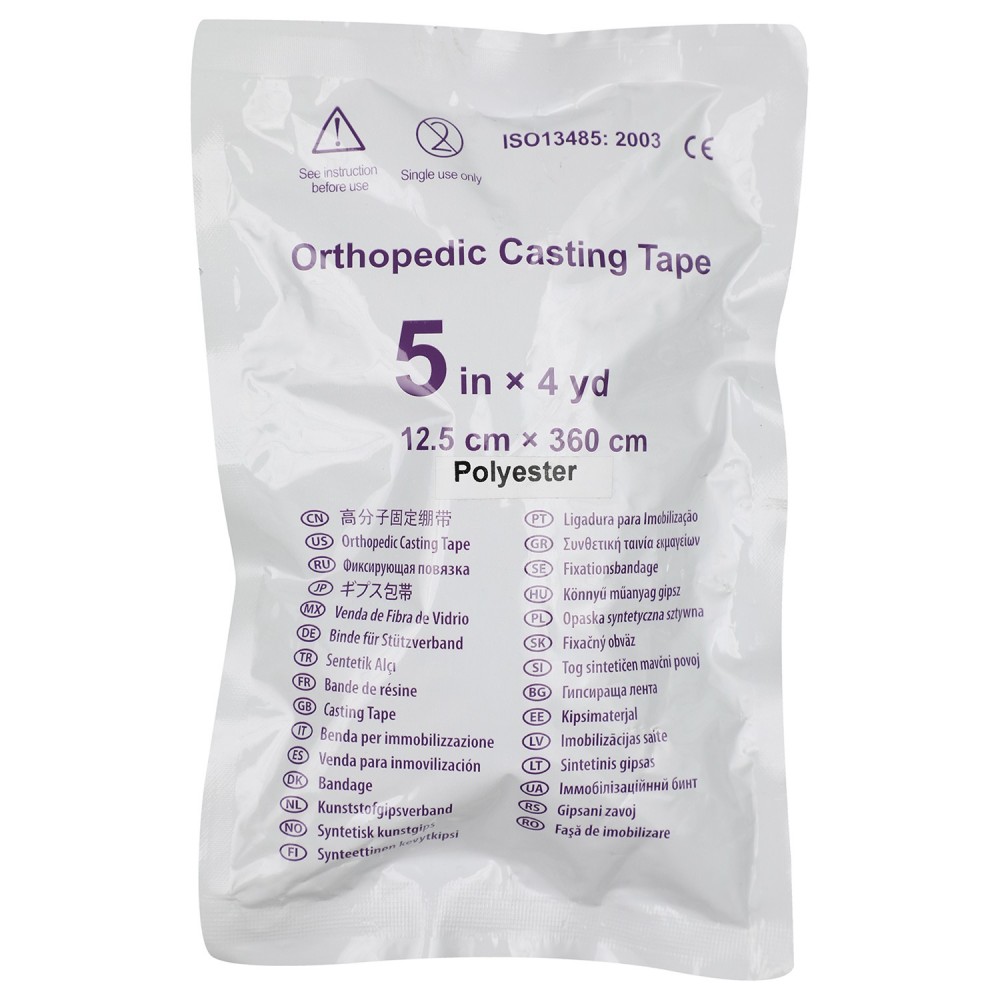

Fiberglass Orthopaedic Casting Tape (Polymer bandage)

Brief Description

1. Instead of the traditional plaster bandage(P.O.P bandage).

2. It is mainly used for the external fixation of fracture or sprain to make the bone heal in orthopedics, plastic surgery and general surgery.

3. Have been obtained the certificates of ISO13485 and CE.

4. Be made of knitted fiberglass fabric daubed water-activated polyurethane adhesive. It has excellent hardness, can protect injured part effectively and is very easy to remove after healing.

5. The fabric knitted by international advanced technology has nice plasticity and air-permeability.

6. With imported polyurethane adhesive it has moderate heat generated when it solidify, suitable stickiness and small moulding shrinkage

7. Good quality, remarkable performance and competitive price.

Characteristics

1. Easy operating to reduce the workload of doctors.

SY fiberglass casting tape is used under the room temperature. The whole operation can be completed in a short time (about 3 minutes). Doctors can make them into any shape according to their demands.

2. Moulding fast

It begins to be solidified after opening the package and being water-soaked. In 20 minutes it can bear weight. The fast molding reduces patients’ affliction or suffering. Though the traditional plaster bandage need more hours for the complete solidification.

3. High hardness and light weight

fiberglass casting tape is 20 times hardness, only 20% weight and one-third thickness of traditional plaster bandage. Doctors can save a lot of bandage material, time and energy.

4. Excellent air permeability

The unique knitted net structure make the bandage many mini holes on the surface to keep good air ventilation and prevent the skin from getting damp, hot and pruritus. This is very important, because many patients may suffer from the skin disease and allergic reaction when they use the traditional plaster bandage.

5. Excellent X-ray radiolucency

Excellent X-ray radiolucency makes it convenient to take X-ray photos and examine the bone healing without removing the bandage. If the patients use the traditional plaster bandage, doctors need to remove it when patients need the X-ray

examination, and the process of removing must cause great troubles to doctors and much suffering to patients.

6 .Water resistant

The absorbed percent of moisture is 85% less than traditional plaster bandage.

Because there are many mini holes on the cast surface, the water surface tension make the water away. Even if touches the water, it still can keep bandage dry.

7. Safety

It has been proved that polyurethane have good biocompatibility, non-toxic and no teratogenic effect though large of animal and acute and chronic toxicity experiments

These excellent performance make our polymer bandage and splint the best necessary orthopedics, general surgery and fist aid products.

Operation

1. Put the padded covering on the affected body part, and twine with the cotton paper.

2. Wear surgical gloves.

3. Before opening the package, choose the roll of proper size.

4. Immerse the cast in room temperature water (21°-24°)for 2-3 seconds and squeeze it 2-3 times.

5. Wrap spirally, overlapping the previous layer by one-half or two-thirds the width of the roll. Just 5-6 layers provide a strong non-weight-bearing cast and 7-8 layers are typically adequate for weight-bearing cast.

6. After water soak the cast begins to solidify in 3-5 minutes and can bear weight enough in 15 minutes according to the need of moulding.

7. SY fiberglass casting tape can be trimmed or removed with traditional cast saw equipment.

Cautions

1. Please wear the surgical rubber gloves before you operate. When the operator is stuck by polyurethane adhesive, please wipe it out with cotton swab with acetone.

2. We suggest you’d better open only one bag each time instead of many bags avoiding affecting the products’ strength.

3. Please use special plaster saw to remove the cast.

4. Take care of them and avoid the cast package is broken to leak air and harden when transport or store.

5. If there is any question, please feel free to tell us or our agent.

Specification

Mode Size(inch) Specification(W×L) Packing

SCF24 2" 5cm×360cm 100bags/4boxes/carton

SCF34 3" 7.5cm×360cm 80bags/4boxes/carton

SCF44 4" 10cm×360cm 60bags/4boxes/carton

SCF54 5" 12.5cm×360cm 60bags/4boxes/carton

SCF64 6" 15cm×360cm 60bags/4boxes/carton

Recommended size for different people

1.2inch for Children’s hands, fingers, and toes

2.3inch for Children’s wrists, ankles, and arms and legs

3.4inch for Children’s legs and ankles, adults’ hands and wrists

4.5inch for Adult’s arms and legs

5.6inch for adult’s arms and legs

Storage

◆Be careful and avoid breaking the package.

◆Please store SY fiberglass casting tape at room temperature.

◆Damaged products by careless handling can’t be returned and exchanged .Please handle and store them carefully.

◆The shelf life of SY fiberglass casting tape is 3 years from the day of production.